Quality Management

Stable quality ensured through controlled processes, laboratory testing and continuous improvement.

We manage quality throughout the entire process – from incoming raw materials through production to final inspection. Each step has clearly defined rules and responsibilities.

How we do it in practice

Standards and processes

Defined procedures, documentation and responsibilities.

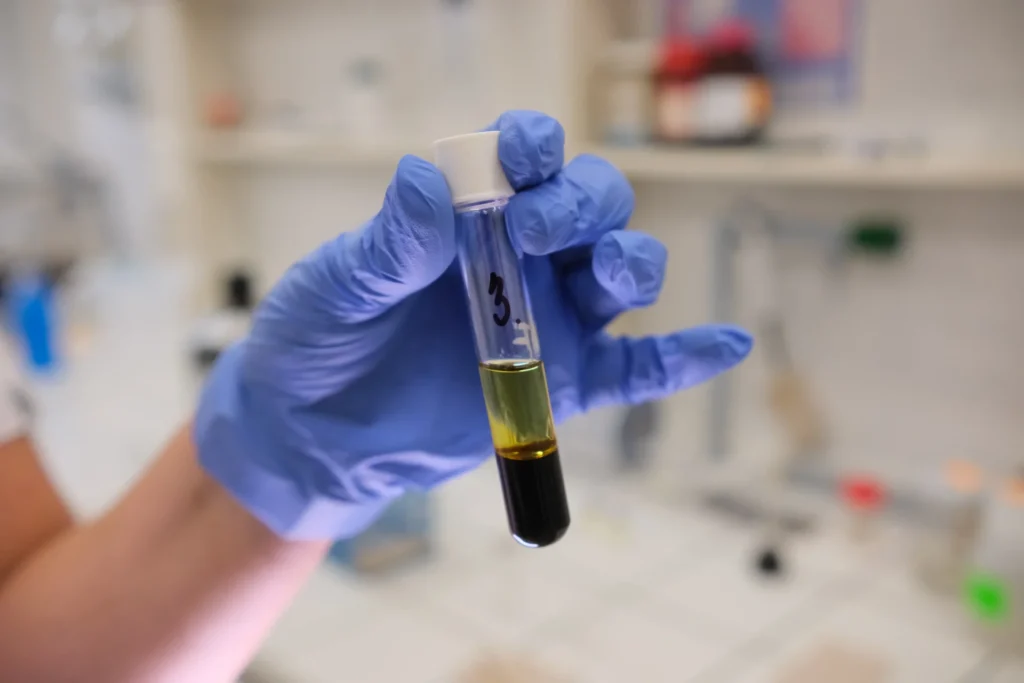

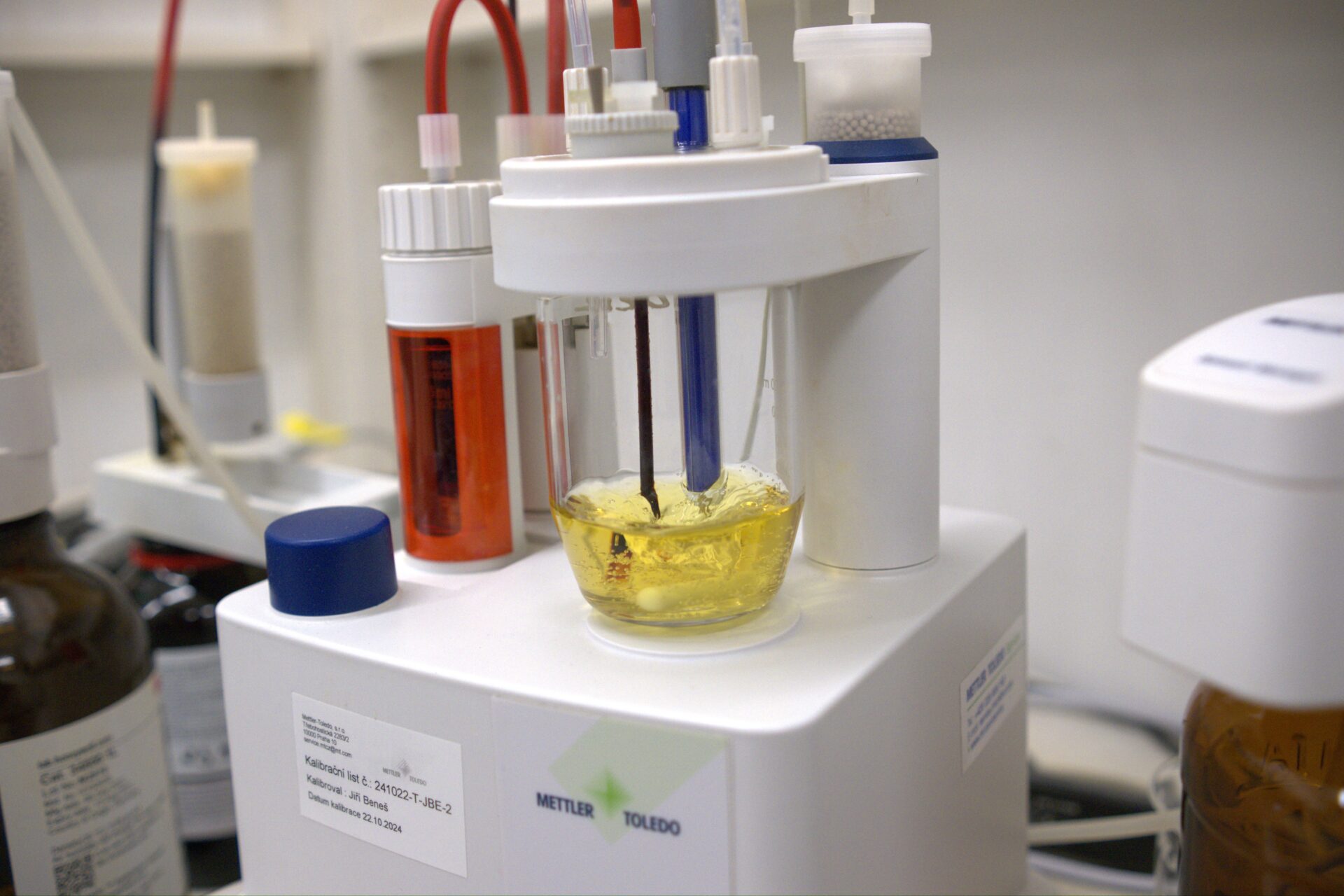

Inspection and laboratory

Incoming / in-process / final inspection and analytical testing.

Improvement and prevention

Monitoring, evaluation of deviations and corrective actions.

100 %

of batches undergo final inspection

All products are inspected according to specification and released only after evaluation.

Quality control step by step

ReceiptIncoming analysis of raw materials

Each delivery of raw materials is verified against specification. Key parameters are checked and materials are released into production only after the results have been evaluated.ProductionIn-process analysis

Production During production, regular sampling and control measurements are carried out. We monitor compliance with required parameters and detect potential deviations in time.ProductionFinal inspection

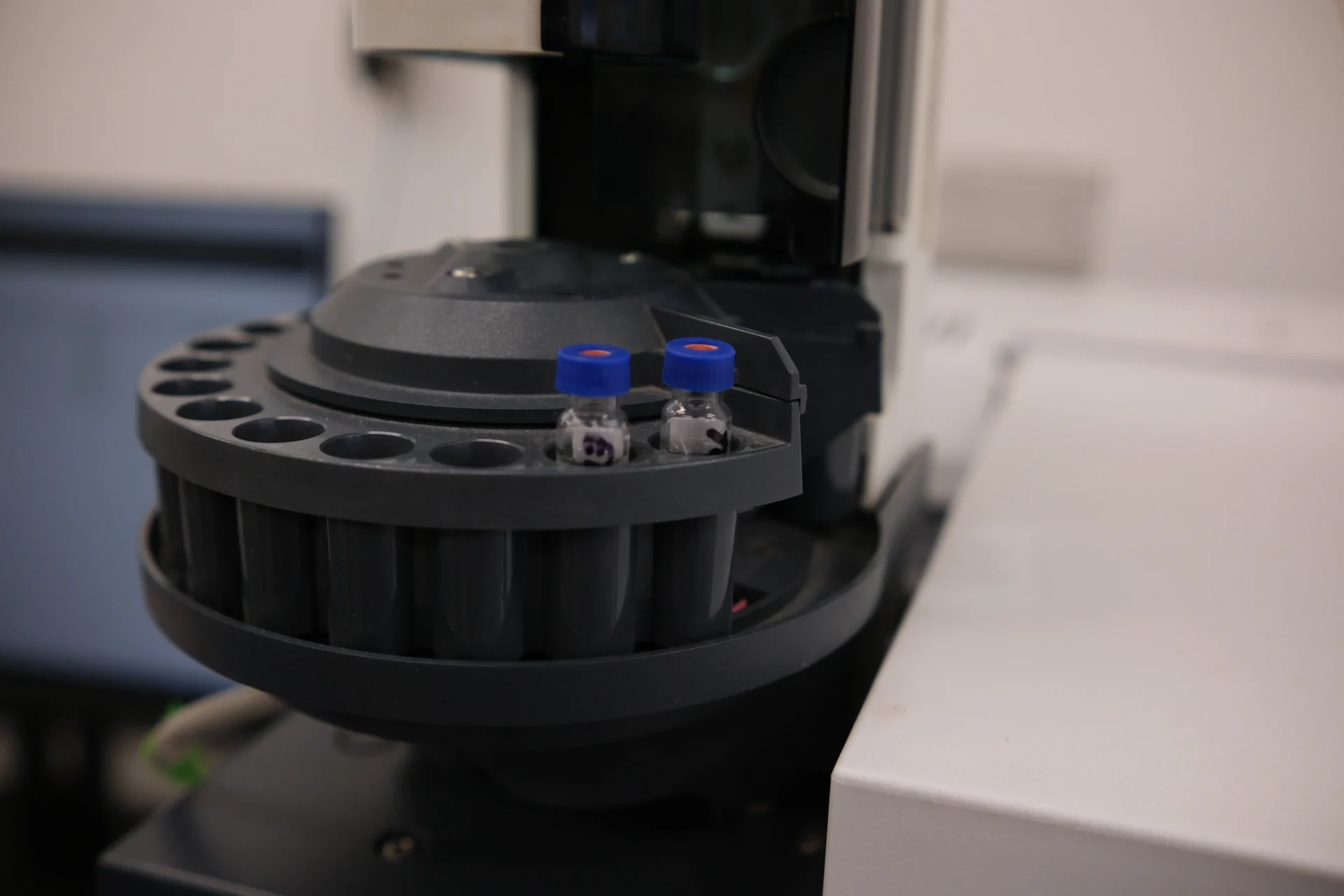

Once production is complete, final batch parameters are verified and compared with the specification. Only after meeting all requirements is the product released for dispatch.ExpeditionFinal inspection and CoA

For each batch, we issue a Certificate of Analysis (CoA), which is supplied with the delivery as agreed with the customer.

Control points

Visual inspection of raw materials

In-process controls during production

Final inspection of finished products

Regular calibration of measuring equipment

Records and traceability of samples

Internal training and qualification

Our quality strategy is based on the following main principles:

- Customer focus – every employee is both a customer and a supplier. Within the plant, employees hand on semi-finished products, services and information. The quality of the final product depends on the quality of work done by all our employees.

- Total involvement – every employee must be involved in achieving quality, understand their role and be informed of the quality requirements for work and products.

- Measurement – monitoring of production and product parameters enables continuous improvement. After all, what is not measured cannot be improved. Measured parameters are defined according to the quality requirements of the final product.

- Systematic support – all activities within the plant must support the pursuit of quality.

- Continuous improvement – employees must work better than yesterday, correct deficiencies, prevent errors and continuously enhance product quality parameters.

- Environmentally responsible behaviour – every employee must act as a guarantor of environmental responsibility, with the primary focus being on reducing the amount of waste we generate and disposing of it in an environmentally-friendly manner.