If you formulate cosmetic products, laundry detergents or industrial cleaners using ethoxylated surfactants (SLES, ALES, ethoxylated non-ionics), it is likely that you have encountered the issue of 1,4-dioxane content. This substance is formed as a by-product during ethoxylation and is attracting increasing attention from regulators and consumers.

A problem that is not (yet) widely discussed

1,4-dioxane is classified as a potential carcinogen. Although its concentration in surfactants is usually low, legislative requirements are becoming more stringent and brands are facing pressure for transparency. For formulators, this creates a clear challenge: how to ensure product safety and comply with regulatory limits?

Legislative reality on the global markets

Requirements differ dramatically from region to region. In the EU, REACH and cosmetic legislation recommend a limit below 10 ppm in the raw material. The US is stricter – California Proposition 65 sets a warning threshold of 30 µg/day of exposure, which in practice results in extremely low concentrations permissible in products.

Asian markets apply their own standards. China, through the NMPA, requires testing and documentation for cosmetic registration. South Korea is gradually tightening K-COSMET standards.

For exporters, it is essential to understand that a single product may require different specifications depending on the destination market. This requires a flexible supplier able to guarantee various purity levels.

Technical aspects: Formation and control of 1,4-dioxane

1,4-dioxane forms through a condensation reaction during ethoxylation, when ethylene oxide reacts with fatty alcohols. The amount depends on reaction conditions – temperature, pressure, catalyst, and reaction time.

Modern manufacturers use two approaches: prevention through process optimisation, and reduction through post-reaction techniques. Vacuum stripping is the most common method for lowering content below required limits. Advanced processes can achieve levels below 5 ppm or even 1 ppm, but this entails higher costs.

The difference between standard and controlled ethoxylation can be tens to hundreds of ppm. It is therefore essential to ask the supplier not only for the typical value, but also for batch-to-batch consistency.

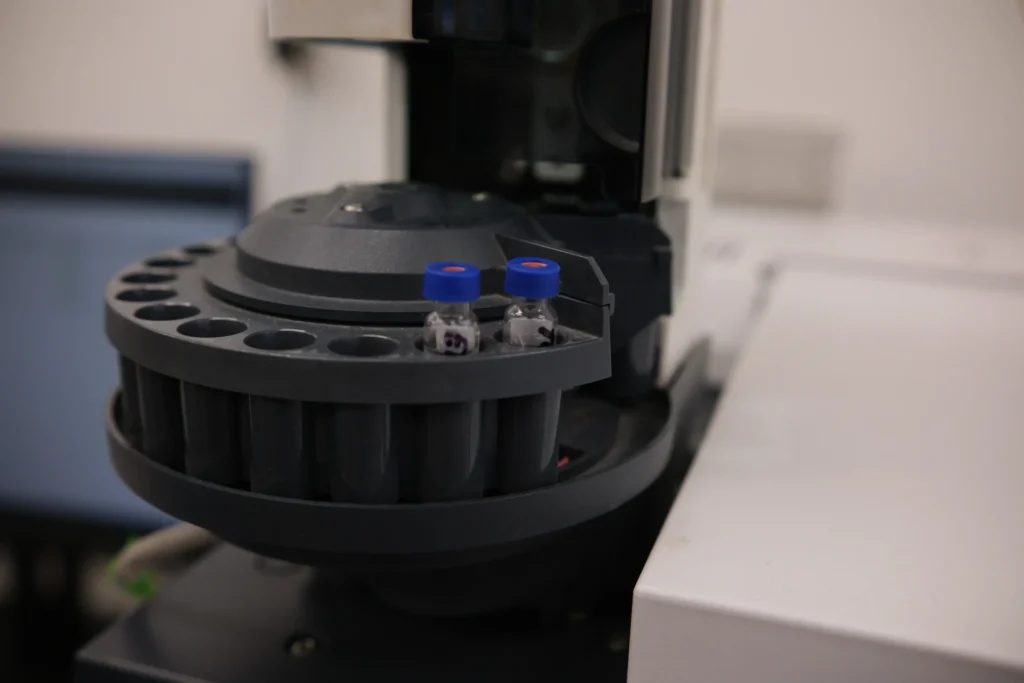

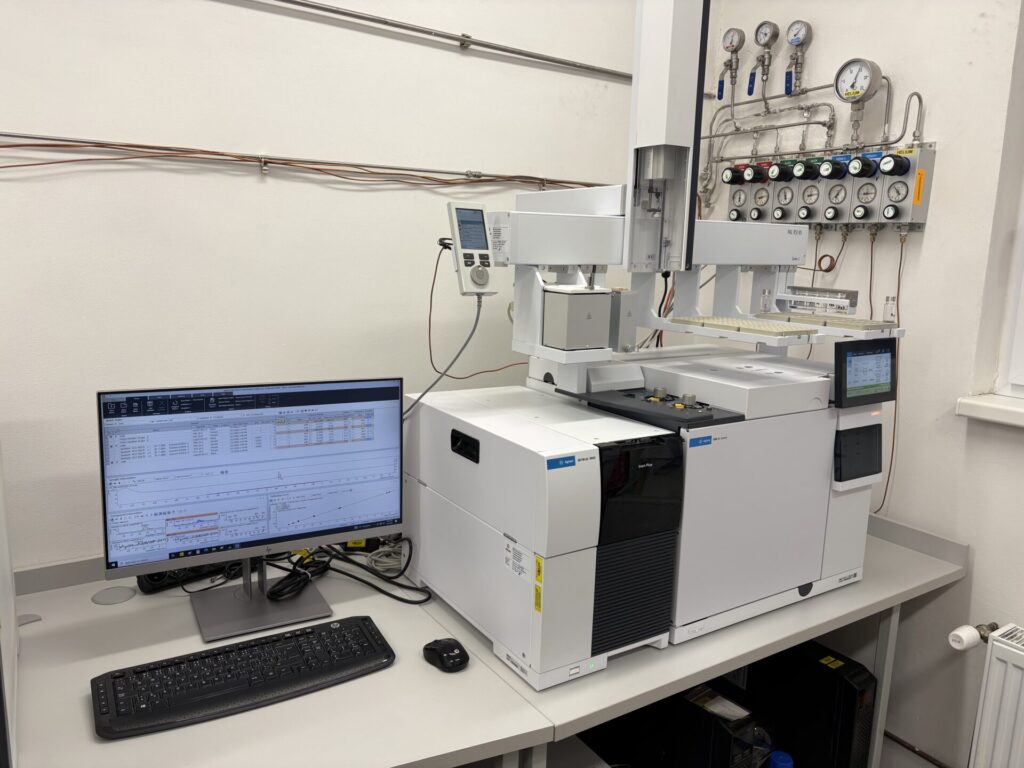

Analytics and interpretation of results

The standard method is gas chromatography (GC-MS or GC-FID) according to ISO/ASTM standards. The detection limit is typically 0.5–1 ppm.

A Certificate of Analysis (CoA) should include the measured value, the method used, the detection limit, and the date of analysis. Batch-to-batch consistency is critical – if a supplier states <10 ppm, ask for the range of values in recent batches. A responsible manufacturer possesses statistical data.

How ENASPOL addresses 1,4-dioxane

ENASPOL takes a proactive approach to this issue. We regularly test our ethoxylated products using accredited methods and guarantee limits according to market requirements – typically <10 ppm, and for more demanding applications <5 ppm or <1 ppm.

For each customer, we provide complete documentation including a CoA with current results. Our technical specialists assist with product selection according to application and target market. Exporting to the US? We provide guidance on Proposition 65 compliance. Entering the Chinese market? We prepare documentation for the NMPA.

We recognise that higher purity means a higher cost. Therefore, we openly discuss with clients where strict specifications are essential and where standard quality is sufficient.

Practical guidance for formulators

Request the following from your supplier: CoA with testing for each batch, specification of the analytical method, and historical data demonstrating consistency.

Set internal specifications: Define limits by product category. Facial cosmetics require stricter control than industrial cleaners.

Communicate proactively: Have a factual, data-supported response ready for customer enquiries.

Monitor the legislation: Requirements are tightening. What is sufficient today may be inadequate in two years.

Controlling 1,4-dioxane is not a rarity but a standard of responsible manufacturing. Choosing a supplier that takes this seriously is an investment in the safety of both your products and your brand.

Need consultation on 1,4-dioxane in your formulations? Our technical team is ready to answer your questions and propose the optimal solution for your specific market.